Lubricating oil analysis is an essential diagnostic tool for monitoring machine performance and planning predictive maintenance.

By identifying wear metals, contaminants, and additives, it is possible to assess the condition of mechanical components, detect early signs of degradation, and evaluate the residual quality of the lubricant.

Today, advanced analytical technologies such as Rotating Disc Electrode Optical Emission Spectrometry (RDE-OES) and X-Ray Fluorescence (XRF) allow for simultaneous multi-element analysis with high precision, short testing times, and no sample preparation required.

Why Lubricating Oil Analysis Matters

Lubricating oil plays a crucial role in mechanical systems: it reduces friction, dissipates heat, and protects components from wear.

Over time, however, the lubricant can accumulate metal particles, combustion residues, or external contaminants.

Regular oil analysis allows operators to:

- Detect wear and corrosion at an early stage;

- Identify contamination by water, dust, or fuel;

- Monitor lubricant efficiency and determine the optimal replacement interval;

- Prevent costly failures and optimize equipment uptime.

In sectors such as heavy industry, mining, transportation, rail, marine, and aviation, oil analysis is a cornerstone of modern reliability and maintenance programs.

Methods and Techniques for Lubricating Oil Analysis

Several analytical methods can be used for oil analysis, but the most efficient and widely adopted is Optical Emission Spectrometry (RDE-OES).

- RDE-OES (Rotating Disc Electrode Optical Emission Spectrometry)

This technique simultaneously measures the concentration of multiple metallic elements (Fe, Cu, Pb, Al, Si, Ni, Cr, Sn, etc.) present as wear particles or contaminants.

It operates through an electrical discharge between two electrodes—one of which is rotating—to vaporize a small amount of oil and measure the emitted light spectrum.

Key advantages include:

- No sample preparation;

- Multi-element simultaneous detection;

- Analysis time below one minute;

- Low operating costs and minimal maintenance.

- X-Ray Fluorescence (XRF)

A complementary technique (Fluorescenze) ideal for elemental and trace contamination analysis. XRF is fast, non-destructive, and applicable to a wide variety of samples (liquids, solids, or residues).

The combination of RDE-OES and XRF provides a comprehensive chemical characterization of lubricants, covering both metallic and elemental components.

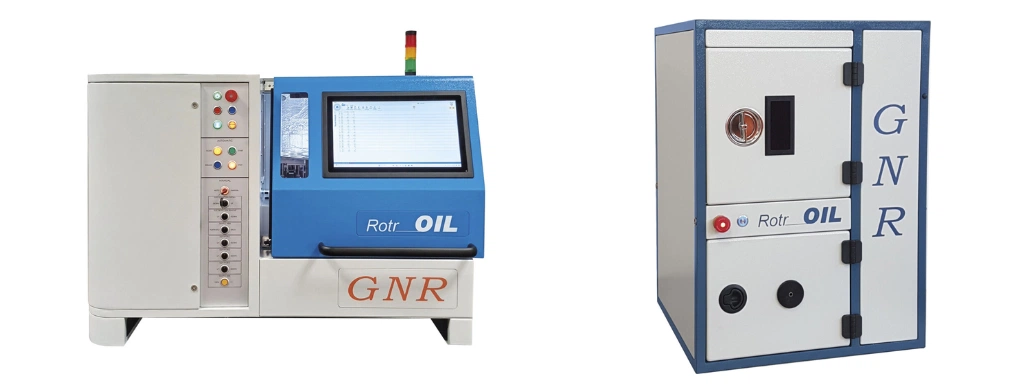

Lubricating Oil Analysis with GNR: the RotrOil Line

The GNR RotrOil line sets the benchmark for oil and fuel analysis in industrial, automotive, and maintenance applications.

Based on RDE-OES technology, RotrOil enables simultaneous multi-element detection in just a few seconds, without any sample preparation.

The system uses a direct electrical discharge instead of plasma or carrier gases, ensuring high signal stability and excellent repeatability.

This allows users to monitor component wear, lubricant degradation, and additive depletion quickly and accurately.

All RotrOil instruments are fully compliant with ASTM D6595 and ASTM D6728 standards for wear metal and fuel contamination analysis.

👉 Discover the GNR RotrOil line

RotrOil Automatic: Automated Oil Analysis for High Sample Volumes

The RotrOil Automatic model is a next-generation RDE spectrometer designed for laboratories that process large batches of samples.

Equipped with an automatic sample changer for up to 48 positions, it performs the entire analytical cycle—from loading to measurement and electrode cleaning—without operator intervention.

This full automation significantly reduces preparation time and operating costs, while ensuring repeatable and traceable results.

Digital control of discharge parameters and integration with GNR’s proprietary data-management software guarantee long-term analytical stability, even under intensive use.

RotrOil: Compact and Portable Oil Analyzer

The RotrOil model is a compact and portable RDE spectrometer that combines robustness, precision, and ease of use.

It is designed to quickly detect wear metals, contaminants, and additives in lubricating oils and hydraulic fluids, delivering immediate and reliable results in any operating condition.

Available in two configurations:

- R2, a lightweight portable version for field or workshop use;

- R3, featuring an integrated PC for complete data management and real-time monitoring.

Both versions comply with ASTM D6595, ensuring accuracy and compatibility with international oil-analysis protocols.

RotrOil is the ideal solution for laboratories, maintenance centers, and fleet operators requiring fast, repeatable, and cost-effective analyses.

Advanced Chemical Analysis with X-Ray Fluorescence (XRF)

Among advanced elemental analysis techniques, X-Ray Fluorescence (XRF) stands out for its speed, precision, and versatility.

It enables the detection of metals, additives, and contaminants with high sensitivity and without altering or consuming the sample.

GNR designs and manufactures state-of-the-art XRF spectrometers for both laboratory and industrial use, offering solutions for rapid multi-element analysis across a wide range of materials.

How to Choose the Right Technique for Oil Analysis

Each analytical technique meets specific requirements, but for lubricating oils, RDE-OES remains the most effective and widely recognized method.

It provides fast, simultaneous, and direct analysis of multiple elements, with minimal maintenance and no sample preparation.

XRF offers a complementary advantage when trace-element or additive detection is required.

Together, these methods ensure comprehensive control for predictive maintenance, condition monitoring, and industrial quality assurance.

FAQ

It is a set of laboratory techniques used to determine the chemical composition, contamination level, and metal content of oils, helping evaluate lubricant performance and machine condition.

The most widely used techniques are RDE-OES and XRF, both allowing precise, fast, and simultaneous multi-element analysis.

To detect early wear, identify contamination, optimize maintenance intervals, and prevent costly equipment failures.

A technique using an electrical discharge to excite a small oil sample and measure the emitted light spectrum, identifying and quantifying metallic elements.

GNR’s RotrOil spectrometers, based on RDE-OES technology, deliver fast and accurate results with no sample preparation, full ASTM D6595/D6728 compliance, and high operational stability.

X-Ray Fluorescence (XRF) is used to detect trace metals, additives, and contaminants without altering the sample, providing complementary information to spectrometric data.